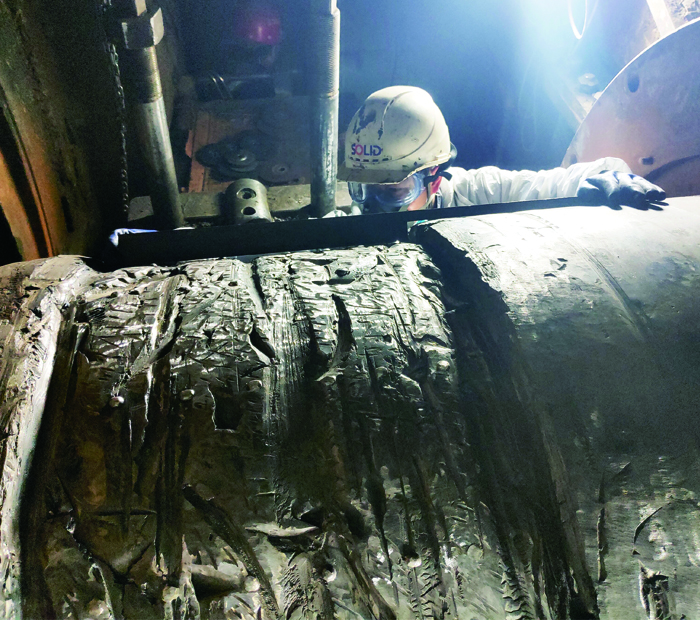

Fretting wear is the primary failure mode for Shaft components. Our shaft wear repair functional materials effectively disrupt the fretting wear mechanism and provide anti-corrosion properties, enabling reliable on-line fast repair.

By integrating the characteristics of shaft wear repair functional materials with precise construction processes, positioning, and material forming control, reliable fast repair significantly reduces disassembly and hoisting workload, minimizing downtime losses, lowering maintenance costs, and extending equipment service life.

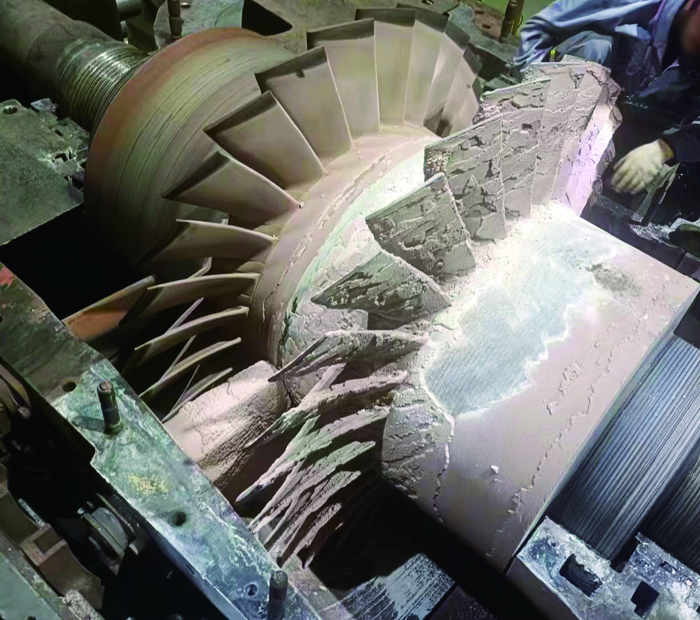

Erosion wear functional materials exhibit excellent impact toughness, corrosion resistance, and fatigue aging resistance, making them advanced materials for managing erosion wear.

Pump cavitation repair materials and technologies optimize flow channel fluid dynamics, enhance cavitation-resistant impact toughness, and offer corrosion protection—delivering an efficient, reliable, and innovative repair solution.

Erosion repair materials and technologies enhance impact toughness of base material surfaces, improve surface hardness, and provide corrosion prevention—thereby significantly extending equipment operational lifespan.

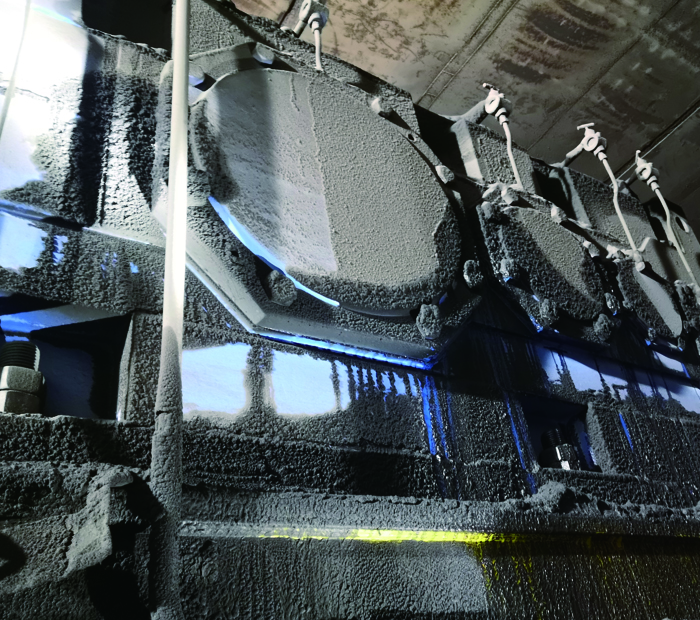

70% of corrosion damage is caused by local corrosion. Our corrosion management functional materials offer heavy-duty anti-corrosion and aging resistance.

Metal weld leak-sealing materials and technologies prevent thermal stress concentration and hydrogen embrittlement associated with welding, providing strong adhesion, aging resistance, corrosion resistance, and high-temperature tolerance for live Leak-Stopping—an effective solution to eliminate leaks and mitigate accident risks.

Heavy-duty anti-corrosion coating materials and technologies provide superior resistance to various acids, alkalis, salts, solvents, and electrochemical corrosion while inhibiting aging and peeling, delivering long-term, high-reliability corrosion protection for equipment.

Green low-carbon functional materials possess basic corrosion resistance, aging resistance, and impact resistance, along with thermal conductivity, hydrophobicity, heat resistance, and thermal insulation, making them advanced functional materials for improving energy efficiency and reducing carbon emissions.

Environmental governance functional materials focus on oil leakage control, featuring strong adhesion and resistance to aging under mechanical vibration stress, serving as advanced functional materials to reduce environmental (soil) pollution.

Green low-carbon governance processes apply to multi-scenarios, including new equipment manufacturing, pre-treatment of newly purchased equipment, and remanufacturing of in-service equipment, ensuring both low-carbon efficiency and extended service life with enhanced reliability.

Environmental treatment processes enable on-line control without disassembly, effectively managing oil leaks, and integrating equipment reliability with environmental protection.

Centered on reliability and targeting failure mechanisms, we provide full-life-cycle health checks, industrial diagnosis, and technical training services. For fluid machinery units (e.g., steam turbines, large compressors, large pumps), We offer holistic solutions for reliability maintenance and performance-improving repairs.

24h engineers service hotline: 86-18678122593(WeChat )

Market Phone:86-0533-3173331

E-mail:suoleigongye@zbsolid.com